Analyse Impact Resistance with Dart Impact Test

BY Victor Admin IN News On 16-07-2019

Free-Falling Dart Impact Test is a material degradation simulation process that can evaluate the impact strength and toughness of the test sample (to do quality comparison on their end-products and raw materials).

This allows manufacturers from various R&D and QC sector of packaging, inspection, plastic film manufacturing and other industries, to study the impact resistance and breaking point of their products.

Evaluation Process

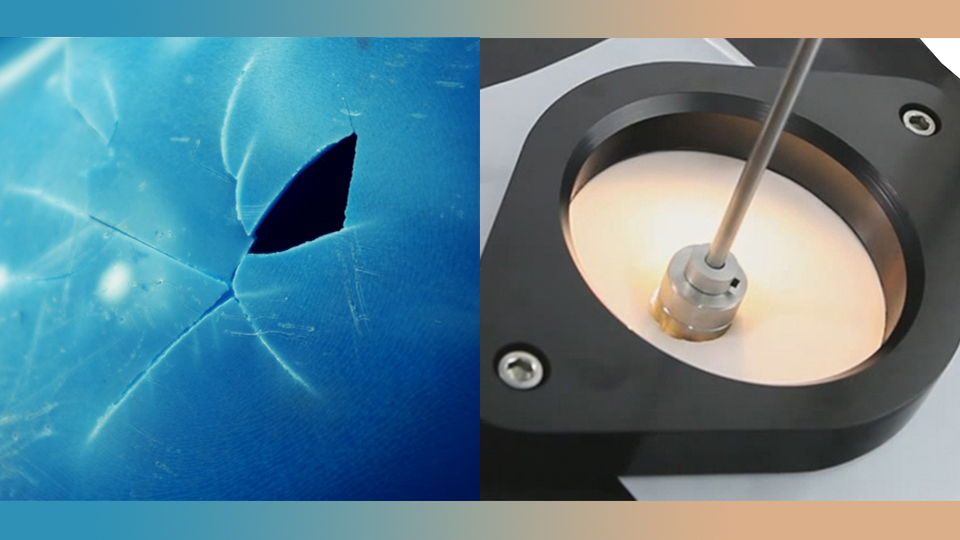

A dart impact test utilises the falling force of the dart to simulate varied impacts by puncturing through the testing sample; this is factored by the size, shape, weight and the drop height of the dart.

Enlightening manufacturers to acknowledge which test sample has the quality and durability needed for their production line.

Benefits

- Determine the impact & force resistance of the testing material

- Product Development Analysis on preventing potential product failure (wear & tear)

- Quality Comparison & Evaluation of each batch of material from old & new suppliers

ABOVE: Plastic Film Manufacturer Customer (from Port Klang, Selangor) was very happy and satisfied with our falling dart impact machine and our support.

Unsure how to perform or need advice on Dart Impact Testing?

Alvin George, Product Specialist (+6012-2232593)

sales11@victormaterial.com cc marketing@obsnap.com

- Browse our Material Testing Equipment via www.victormaterial.com

- View our list of Services at www.victortestingmachine.com

5 years ago / Comments Off on Analyse Impact Resistance with Dart Impact Test

Comments are closed here.