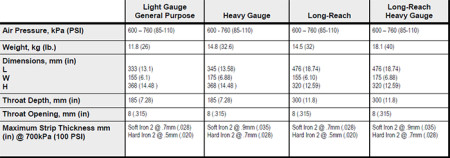

The STRIP-LOK™ Sheet Metal Joiner is a portable strip-joining machine driven by compressed air. The main use for STRIP-LOK™ joiners is repairing strip tear off situations on modern steel strip processing lines such as continuous galvanizing and paint coil coating lines. Four models are available to suit most production facilities. This is the best advance in economical efficient and effective strip joining equipment in over three decades. Already used by major US, Canadian and Australian steel manufactures, the STRIP-LOK™ Sheet Metal Joiner is highly appreciated and valued.

Repeatable, strong connections can be achieved with a total sheet thickness up to 1.8mm (0.07″). Operation is very clean and quiet as the STRIP-LOK™ Joiner does not require any consumables other than the two pieces of strip to be joined and no blank is produced.

Joint Strength

The strength of each join depends upon the gauge and properties of the metal being connected. As a general rule, 20 punches on each side of .4mm soft iron sheets provide a tensile force of approximately 25kN (5620 lbf). If joining two sheets of different thicknesses, always place the thicker material on the underside. Note: A light application of lubricant on the sheets being joined or on the punch will facilitate operation when joining thick sheets near the joiners upper capacity.

Principles of Operation

The joint is achieved by mechanically punching a square hole through the sheets to be joined and folding the flared strip back onto itself.

Apart from requiring an external compressed air source the STRIP-LOK™ Joiner is fully self contained. The STRIP-LOK™ Joiner is activated as soon as the trigger is pressed and an automatic cycle of punching and flattening the two layers of metal strip will then commence. The joining cycle will immediately stop as soon as the trigger is released.

Warranty Information

STRIP-LOK™ Sheet Metal Joiners are manufactured using only the highest quality materials and workmanship. The light weight housing is manufactured using a high strength grade aluminum alloy and the punch and die are manufactured using high strength tool steel which is hardened and heat treated prior to assembly. The joiners are fully bench tested in the factory prior to shipping.

A six months warranty from the date of purchase to the original owner is provided covering workmanship and materials of construction. The warranty does not cover miss-use. The supplier or manufacturer may decide at their discretion to repair or replace faulty equipment. A charge will be applied covering repairs to equipment damaged through miss-use, including damage resulting from the use of contaminated compressed air.