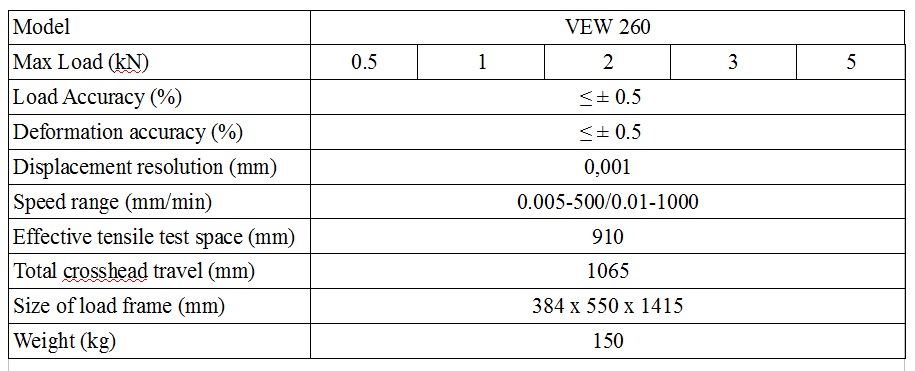

- Max. Load: 500N;

- Load accuracy: better than ±1%;

- Deformation measuring accuracy: the relative error of indicating value better than ±1% within measuring range;

- Displacement resolution: better than ±0.01mm;

- Displacement measuring accuracy: better than ±1% of indicating value;

- Speed range: 0.05mm/min—500m/min, steppless

- Speed accuracy: better than ±1% of indicating value;

- Max. Tensile travel: 650mm

- Control mode: Possess three kinds of close loop control modes, namely load, deformation and displacement, to realize no impact switch during automatic program control test;

- Protection function: Possess overload protection, limited position protection function, and over current, over voltage, over speed, over torque and over heating protection of AC servo speed-adjusting system and the motor;

Electronic Universal Testing Machine

This Model Electronic Universal Testing Machine is designed and manufactured according to National Standard & ASTM E4 standard. It is computer-controlled precision Testing Machine, suitable for wide range of material for tension, compression, bending and shearing test. It has high stability as well as high precision, equipped with PC system & printer for graph, test result display, printing & data processing. Complete with modulus for metal, spring, textile, rubber, plastic and other material testing & creep test. It is widely used in many fields such as industry factories, mineral enterprise and high schools.

Load frame

- Single column high rigidity frame designed with to assure high resistance

- Movement of the movable crosshead obtained by pre-loaded ball screws to eliminate the backlash.

- Working area easy to reach.

- Reduced overall dimensions.

English Version Software

- Full digital control

- The whole measuring and controlling system adopts specific PC control card used for testing machines, realizing the data zero and plus adjustment, which has very high reliability

- Supporting multi-transducer

- Realizing the database management of the test data, which are stored according to the standard format facilitating other software to analyze and transfer.

- Realizing the database management of the test data, which are stored according to the standard format facilitating other software to analyze and transfer.

- Perfect programming by auto program control, every control mode can smoothly shift to another one. Fulfilling the test requirement of all kinds of materials with every test standard home and abroad.

- Control software has the auto-adjusting function of test hardness, which assures that the system works with every kind of specimen hardness.

- Perfect graphic function realizing the arbitrarily magnifying, decreasing, equaling, adding, indicative display and print of all kinds of test curves, the test point searching as well as the simultaneous display and print of several kinds of test curves. Data processing supposes self-disposing and input disposing of graphic human computer interaction, which facilitates the check and contrast of the test result.

- The clients can self -define the output of the test report, which makes the report format have very high flexibility