Metallographic Welding Preparation

BY Victor Admin IN Uncategorized On 20-02-2019

Around the 19th century, welding was introduced by joining sections of metal by forge welding (i.e. heating & hammering it). Today welding process like fabrication (for joining materials regardless of compositions, parts, shapes and sizes) are commonly used.

Aircraft & Aerospace, Shipbuilding & Marine, Land transportation / Automotive, Oil & Petrochemicals, Domestic & Metal Furniture are some of the well-known industries that uses welding.

Since welds are usually made by different materials, it is important to choose the right metallographic preparation method to analyse its quality.

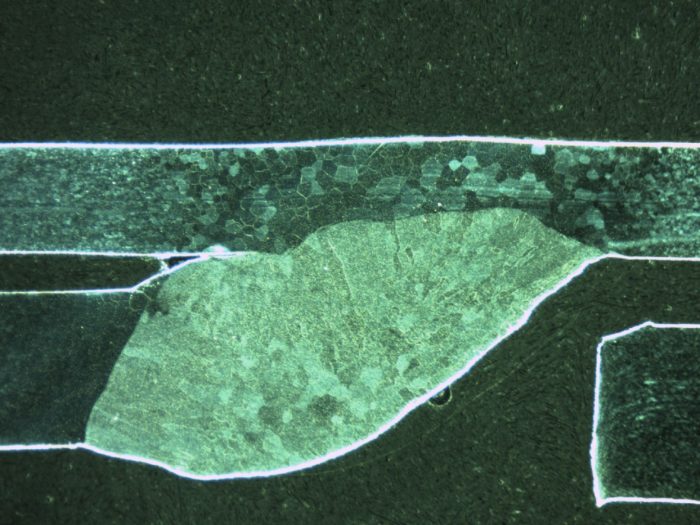

For Refinement, Research & Development and Analysis, Metallography is applied to access the different aspects in a weld e.g. depth of penetration, extent of Heat Affected Zone (HAZ), and other defects i.e. pores and cracks on representative work pieces.

Proper preparation methods are needed to study the mircostructure and properties of the welded region.

Weld Microsections Examination Process :

Cutting / Sectioning :

The first process of preparing the specimen for metallographic or microstructural analysis. After choosing the desired area of interest, sectioning and cutting will be applied.

To avoid deformation from cutting while lowering the risk of thermal damage on the cut surface:

1. Use the correct type of abrasive cut-off wheel

2. Use appropriate feed speed

3. Have an adequate level of coolant given during the cutting

Mounting :

Mounting creates a mold around the specimens to provide protection and suitable & consistent sizes to be later used for the next preparation and examination steps.

Usually, macro sections for testing are unmounted due to time constraints, and the finish is usually adequate.

If semi-automatic preparation, then there are a number of specimen holders which will accommodate those sections from the welded joints. If mounting required there is an option of compression mounting.

It is not uncommon, weld examination have large cross sections.

Electrolytic Polishing / Etching :

After cutting and grinding, the specimens are later electrolytically polished and etched to provide a section suitable for macro examination. (To corrode or eat away the surface of top layer of the specimen; thus revealing the microstructures of the material for microscopic examination)

This provides:

1. Speedy and easy use of operation

2. Minimizes user contact with acidic etchants

3. Capable of handling stainless steel types and other metals that are difficult to etch just chemically.

Electrolytic Polishing / Etching :

After cutting and grinding, the specimens are later electrolytically polished and etched to provide a section suitable for macro examination. (To corrode or eat away the surface of top layer of the specimen; thus revealing the microstructures of the material for microscopic examination)

MECHANICAL PREPARATION TYPE:

Macro sections Depending on the hardness, parent material, heat affected zone, and metal welded of the specimen. A silicon carbide paper can make a specimen more suitable for macro etching and for weld macro examination later… The cutting life of the silicon carbide paper can last between 1.0-1.5 mins and this exacerbated (intensifies) with increased section size.An alternative for grinding/fining for manual preparation,

the Akasel Aka Piatto can offer:

1. Longer Cutting Life

2. Constant Removal Rate ≥ Longer Time Period

3. Suitable for a wide range of materials hardness (HV150-2000)

4. Produce Less Wast.

Micro sections The weld’s material hardness can vary from one specimen to another. This is caused by phase changes during a welding, or because the joint has different metals incorporated in it. Sometimes a weld metal can contain age hardening (or particle hardening) or unexpected welding defect. The preparation is important to ensure minimal polish relief between micro structural features and that all micro structural elements are retained for examination. Semi-automatic or automatic preparation equipment for the wide range of welded materials; can provide consistency and reproducible of the polish which can facilitates accurate micro structural analysis.

5 years ago / Comments Off on Metallographic Welding Preparation

Comments are closed here.